How is leather made?

The production of leather, especially tanning, is a complex process with many individual steps. Tanning is the preservation of animal skin for the purpose of use/processing.

From animal hide to fine leather

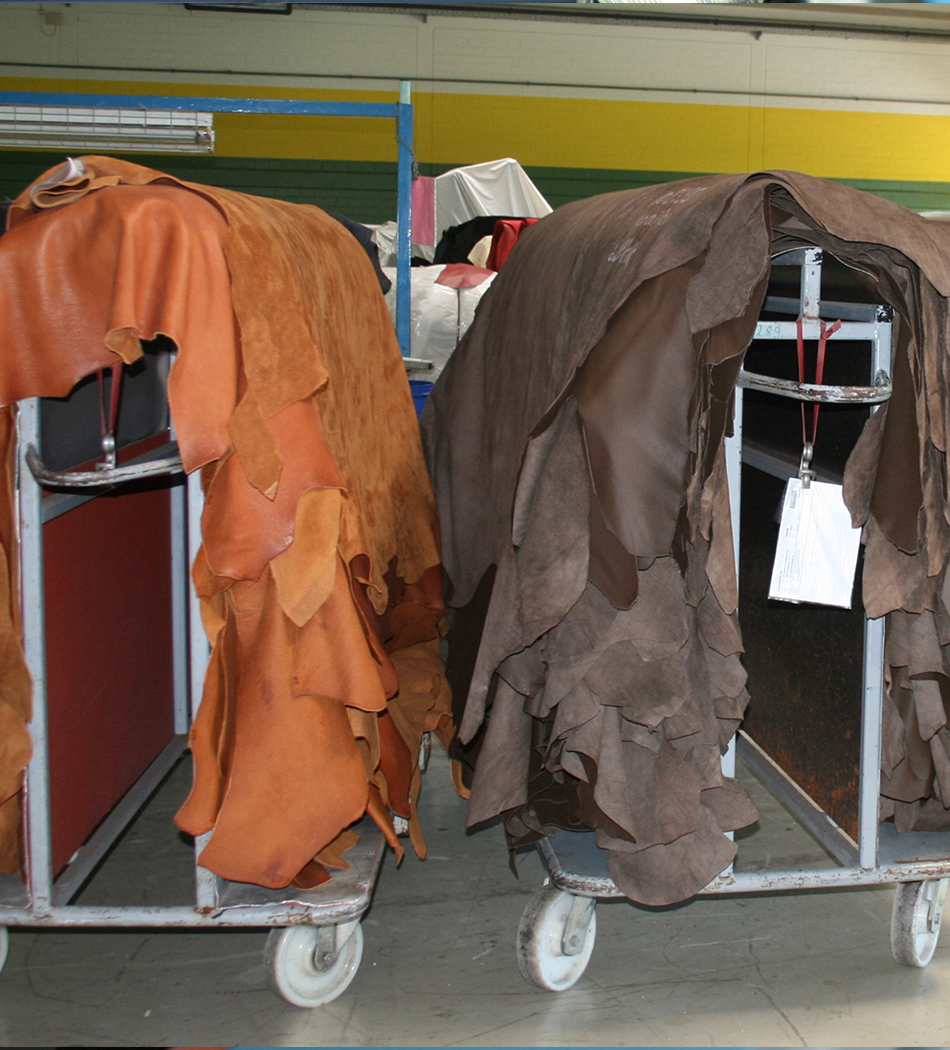

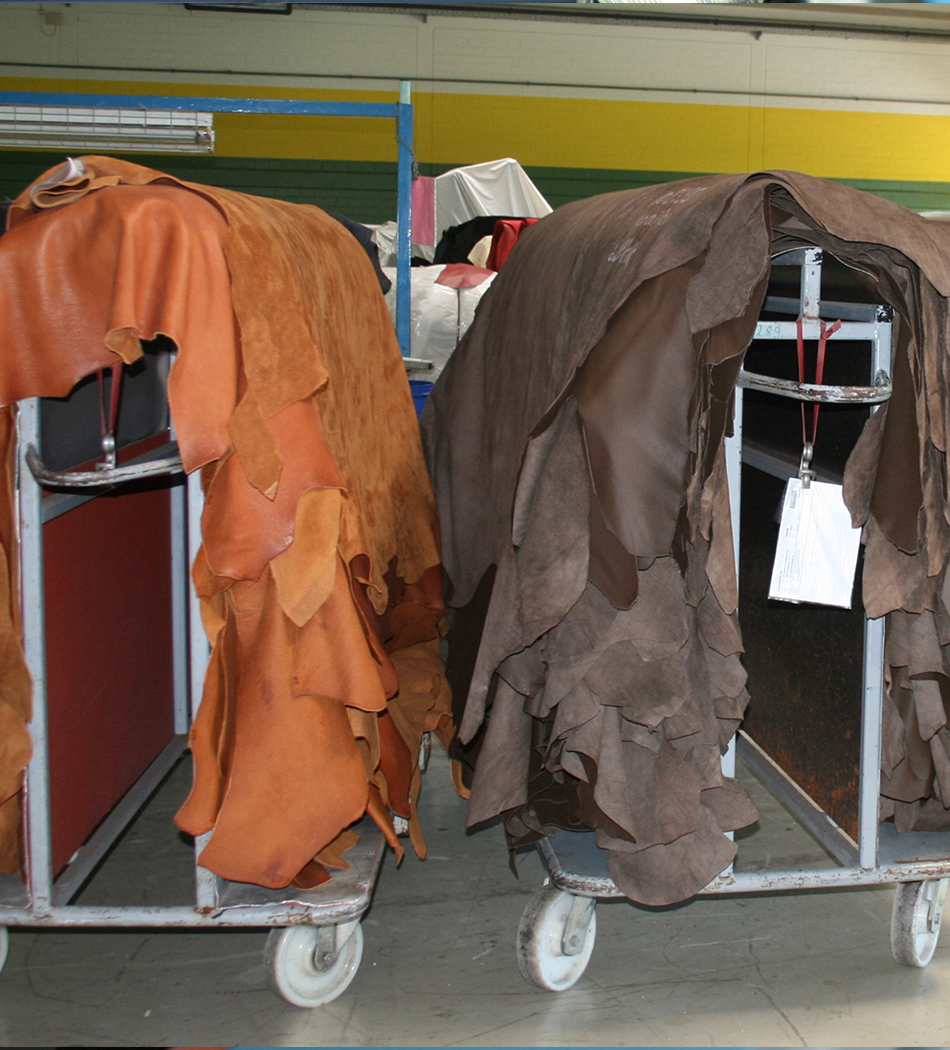

For furniture leather, cowhide is almost exclusively used, as it has sufficient stability and thickness and is therefore particularly hard-wearing. Animal hides are a waste product of the food industry and the raw material for leather production. The tanneries usually obtain the animal hides from the slaughterhouses via raw material traders.